There is no mains drainage available at the site so the plan has always been to use a small sewage treatment plant for the new house and to install this early so it can also be used by the static caravan during construction. The old house had a traditional brick septic tank, discharging into the field drainage ditch, but this was well past its best and those old designs simply cannot match the treatment quality of modern systems.

Some time ago I settled on using a Biorock system. These are one of a handful of designs that don’t require an electricity supply: most other systems rely on either an aeration pump or rotating discs to treat the effluent whereas the Biorock system relies on natural ventilation of a treatment unit with aerobic bacteria hosted on a stack of foam cubes contained in string bags. While a Biorock unit is more expensive than the alternatives the zero electricity cost offsets the higher purchase price relatively quickly and the sheer simplicity of the system is very appealing.

Upstream of the main Biorock treatment unit there’s a separate, large settlement tank divided into two sub-chambers with a brush filter on the outlet which keeps solid matter out of the Biorock unit itself. Downstream of the Biorock there’s a small vertical access shaft for sampling the final discharge quality or, if necessary, for installing a pump to raise the treated effluent to a higher level. One characteristic of the Biorock system is that the main treatment chamber is relatively dry, holding just a shallow layer of water at the bottom, and as a result the outlet is 1.15m below the inlet and the outlet must be allowed to drain freely. On a flat site this means a pump is often required whereas on a sloping site it can be possible to do everything by gravity. On my site it proved just possible to arrange for a gravity outfall to the same drainage ditch used by the old septic tank, though some of the pipe runs are at the minimum permitted gradient (1:200 for treated effluent) and the Biorock unit needed to be located with the top roughly 0.8m above the current ground level in its immediate vicinity. The ground level will be raised later as part of the site landscaping scheme.

With the Biorock being relatively unusual in the UK (my architects, my structural engineer and my building control inspector had not come across one before) there aren’t that many installers who are experienced in the specific requirements and I wanted to ensure the installation was done correctly. Biorock UK recommended Mike Welton of Welton Environmental and Mike did a great job, installing the tanks and about 50m of inlet and outlet pipework in 3 days with just the help of a good local JCB and operator.

Different sizes of Biorock units are available to cater for different sizes of dwelling, based on the “Population Equivalent” (PE) definitions of e.g. the British Water standards. The smallest 5 PE unit is suitable for a 3-bedroom house, but since my house will have more bedrooms than that I needed the next size up, the 10 PE, which is good for up to 8 bedrooms. This is paired with a 3,300 litre primary tank, and then although I don’t (currently) need to pump the outlet it seemed like good insurance to install the 400mm diameter “pump shaft” rather than the 160mm diameter “sampling tube” just in case a pump is required to help the flow along at a later date.

With the tanks raised out of the ground more than would be normal on most sites they didn’t require too deep a hole and the ground conditions were good.

Due to a couple of hiccups with deliveries (the first primary tank had a hole in it but Biorock UK managed to ship a replacement overnight, and then the concrete plant sent a regular wet mix rather than the requested dry mix which took 3 hours to correct) I wasn’t able to be present for the actual installation but I took photos once I got back from work.

The primary tank (foreground) and the Biorock tank with dry-mix concrete back-fill.

The inlet pipe (left of shot) is just temporary to permit the tanks to be partially filled to balance the pressure of the back-fill.

Once covered with soil up to what will become the new ground level the tanks look less prominent. From left to right, the visible features are:

- The air intake pipe (110mm diameter, black, approx 600mm high)

- The cover for the 400mm diameter pump shaft / sample chamber

- The alarm rod (40mm, grey; connected to a float to indicate if the water level rises too high within the Biorock unit)

- The cover for the Biorock unit

- The temporary ventilation pipe for the Biorock unit (110mm diameter, black; rises to approx 4m, out of shot)

- Once the barn is re-built this will be relocated and attached to the side of the barn but for now it makes sense to keep it well out of the way of the demolition and construction work

- The cover for the brush filter on the outlet from the primary tank (110mm diameter, grey)

- The cover for the primary tank

There’s nothing much to see within the primary tank (it’s just a tank, with a baffle about 2/3 of the way along) but the Biorock unit is a little more interesting. Mike tells me the foam cubes come impregnated with a bacteria culture to kick-start the treatment process once they get wet.

The view in the top of the Biorock unit, showing the grey effluent delivery pipes and the foam media inside orange string bags

While sewage treatment might not be the most exciting aspect of the new house this installation marks a milestone as being the first part of the permanent construction to be completed and so it feels like a pretty big deal.

Update 2015-06-28

After just over a year, the Biorock system is still working perfectly. The soil around the tanks had grown lots of weeds so, since this is a permanent installation and part of the future garden, I decided it would be better to lay some gravel to stop the weeds and tidy up the area. While that’s not quite as simple as it sounds – the gravel needs some sort of enclosure and there needs to be a layer of landscape fabric to stop the weeds growing through the gravel – the finished result looks good. I also secured the bottom of the vent stack in concrete to stop it moving.

Update 2016-07-03

Another year on and the system has been working perfectly – up until recently. The new house has been under construction since October 2015 with a small core team on-site every day and various subcontractors coming and going at other times. Somewhere down the line one of the subcontractors evidently thought it was acceptable to flush kitchen towels down the site toilets. This would be asking a lot of mains drainage and was never going to turn out well with a system like the Biorock. The brush filter on the outlet from the Primary tank stops anything getting into the Biorock unit itself but it’s still possible to get a blockage at the inlet to the Primary tank.

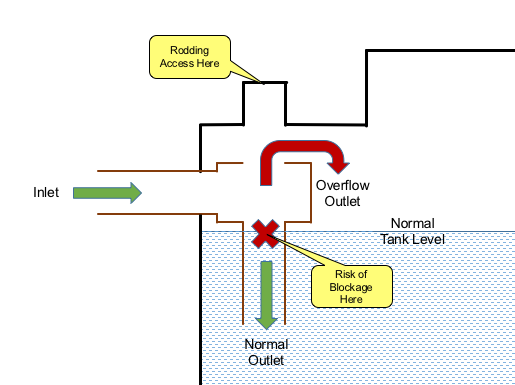

The problem showed up as a raised water level in the manhole leading to the primary tank. Rodding it helped temporarily and definitely moved water into the primary tank but the level in the manhole didn’t drop. It took a while to work out what was happening and there’s not much to see from inside the Primary tank – just a translucent white box around the inlet – so the cross-sectional sketch below should help to make things clear.

Under normal circumstances the sewage flows in from the left and then drops into the vertical tube. Generally that works fine and everything clears down the tube but there’s a risk of a blockage forming near the top of the vertical tube. If that happens there’s an overflow out of the top of the white plastic box, but that’s roughly 150mm above the normal tank level – hence the raised level in the upstream manhole.

The only way to clear such a blockage is to come in from the top of the tank and rod down the vertical tube. There’s an access point (possible air vent location?) moulded into the top of the tank which is directly above the vertical tube (I wasn’t completely certain that would be the case, but it is) and for my installation that was still closed off and I had to cut the top off with a hacksaw.

Not predicting the need to gain such access I’d foolishly located the end gravel board directly over the centre of the access port! My Plan A was to permanently fit a screwed rodding point at ground level but I can’t face re-working the gravel boards right now so I just fitted a flexible rubber end cap and put the gravel board back over it. The “pipe” is nominally 110mm diameter but it is moulded in thick polythene and not as accurate as an extruded PVC pipe would be, so a flexible coupling secured with a stainless steel Jubilee clip is a good way to go.

Judging by the drawing of the latest specification of BIOROCK-ST1-3000 Primary tank from the Biorock website (PDF link here) it looks like it might now be standard practice to fit an accessible rodding point in this location. I’d definitely recommend doing that on any new installation.

Despite this minor setback which was directly attributable to misuse of the system it’s working very well and I continue to thoroughly recommend the Biorock products. The quality of the treated discharge remains excellent.

Update 2020-08-01

When originally installed the two ventilation stacks for the Biorock tanks were fitted with simple grilles to keep birds and debris out. While working on the dressing room which has one of several Air Admittance Valves for the drainage system I noticed that in some wind conditions the drains were being pressurised relative to the house and the AAVs were lifting slightly and venting the drains into the house.

The fix for this was to fit a wind-driven rotating cowl to the ventilation stack on the primary tank, which also vents the house drains. Some of these cowls can be reasonably expensive but I found a 100mm unit for £39.99 from fans4less.co.uk which seemed like it was worth a try. It’s early days but the results seem pretty good and I’m now going to fit a matching cowl to the vent for the secondary tank too.

|

Looking again at the Biorock website, there seems to be a stronger recommendation than I remember to fit these sort of wind-driven cowls as a matter of course and they have a new Wind-Driven Ventilator (PDF data sheet here) which looks nicely engineered (and only suitable for ventilation since it’s made of plastic) but it’s €150. Both my vent stacks are only temporary-ish (they’ll be mounted on the re-built barn whenever that gets constructed) so I’ll review whether to swap to the Biorock ventilators when that happens, depending on how the bearings on the cheaper models hold up.

Update 2023-11-01

Three years on and the cheap wind-driven ventilator has seized up. I removed it to check if the bearings could be replaced and found it was all very badly rusted – surprisingly more so on the sleeve that fits inside the pipe than on the blades themselves. On reflection, a coat of spray paint might have helped.

Researching for replacements, my preference is now for the Biolan Wind Fan which is specifically designed for ventilation use-cases. It’s made of aluminium so should resist corrosion – plus it’s painted black. Judging from the instruction manual, the bearings seem more accessible and maintainable, and it will always tend to be the bearings that limit the life of these units.

![]() Biorock Sewage Treatment Plant Installation by Marsh Flatts Farm Self Build Diary is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Biorock Sewage Treatment Plant Installation by Marsh Flatts Farm Self Build Diary is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Hi,

I am interested in the Biorock sewage treatment plant for the same reasons as yourself regarding cost effectiveness and reduced maintenance. I guess it is early days for a review but wondered how well the plant has been working for you so far.

Regards

Heather

Hi Heather,

Well, it certainly is early days but everything is working fine so far, and there’s really not much to go wrong. I’m not really stretching the unit at the moment since it’s sized for 10 people and there’s only me using it right now. The quality of the water treatment seems very good, even though it hasn’t had chance to grow many bacteria in the primary tank yet – as it’s been fairly dry recently there isn’t much other water in the ditch the Biorock drains into but the puddle that gathers there is clear and doesn’t smell at all.

David

Hello David.

It’s been a while since your last feedback regarding the Biorock system. We are in the process of choosing the right system for ourselves and have the Biorock system as firm favourite at the moment, based on the same reasons as yours. Could you give further feedback regarding your experience of the system ’til now?

With thanks and best wishes

Annie

Hi Annie,

It’s very much a question of “no news is good news”. The system has been installed for nearly a year now and continues to work perfectly. It’s still having a pretty easy time of it with only light usage but I’m very happy with how it’s performing.

I’m glad I chose the Biorock and I’m particularly pleased it proved possible to install it without needing to pump either in or out so that everything flows by gravity. It’s fundamentally a very simple system, with little to go wrong, and yet it treats the waste to a very high standard. Since the outfall from my unit is to a field drainage ditch it’s easy for me to keep an eye on the treated water and it’s always clear and never smelly.

I would recommend taking the cover off the Biorock tank every few months – especially when it’s new and might still be settling in the ground – to make sure the grey pipes (as in the last photo) are completely level and draining freely and evenly, and to keep an eye on how soon it might need servicing.

David

Hi David,

Great post.

We are considering replacing the ceptic tank system we have in the house we have in the house we have just brought and are looking at a 10 person system.

So I have a couple of questions:

– The first is, how are you getting on with the system?

– The second, and please do choose not to answer this one if you don’t want to, how much was the total cost to buy and install the unit?

Have read about one family who had a poor installation and things went a tad wrong, by the sounds of it the only issue you seem to have had so far was the blockage. Is that still the case?

Cheers,

Mike

Hi Mike,

My Biorock is still working fine and I’d choose the exact same system if I was making the decision again now. Reducing energy consumption is important to me and the fact that the Biorock doesn’t rely on an electric pump or motor is a major benefit from my standpoint (plus there’s less to go wrong).

If you have an old septic tank then I’m sure you’ll find the Biorock will do a much better job of treating the effluent. My main advice would be for you to review how you’d meet the extra requirements the Biorock imposes:

– It needs one ventilation inlet and one or two ventilation outlets (depending on whether the existing vent pipe on the house can act as the outlet for the primary tank) and the outlet(s) need to be 4m high and relatively close to the tanks, so you need to consider where those would go.

– Unlike a septic tank, the Biorock unit (the second tank) runs “dry” and so the outfall pipe needs to be quite low down. You may need to install a pump, depending on where you’re discharging to.

As with most things, you really want an installer who is familiar with the product and understands how it might be different from what they’ve used previously. Mike Welton was recommended to me by Biorock UK as someone who has installed several of the systems, and Mike certainly knows what he’s doing.

I won’t share the pricing details here but I’ll dig out the invoice and send you an email later.

David

Hi David,

I too am researching Biorock as a solution to our sewage plant requirements up in North East Scotland, Aberdeen. We’ve been recommended a Tricel Treatment Plant with integrated pump with secondary treatment by a Puraflo Peat Tank and outflow to a 150m2 Soakaway.

The cost for Tricel and Puraflo system and the Soakaway is about £17,000(!) and then on top of this is the yearly running costs for electric and emptying.

We have gravity on our side as the house is elevated from the garden and runs downhill. We also potentially have access to field drains that run through our land and if feasible, output the treated liquid from the Biorock to this culvert.

I have contacted Biorock for a quote. I am just getting my thoughts out there. You are obviously happy with your system.

I just hope there is an installer for Scotland, it is cost effective to install and I can output the treated liquid direct to the culvert.

Hi Kevin,

Yes, I’m still very pleased with my Biorock system; for me I’m happy it was the best way to go – largely fit-and-forget (though I do lift the lids off the tanks every few months just to check everything is still OK, and I do keep an eye on the outfall into the drainage ditch).

It does sound like the Biorock would work in your case – if the levels work out so you can run everything with gravity and you have access to a field drain to discharge into that sounds ideal.

David

Hi David,

I’m living in Mallorca (where water is a scarce and expensive commodity). I’m looking at installing a black/grey water system so I can recover water for irrigation. Do you have any thoughts on whether the discharge would be ok for that use?

Thanks,

David

Hi David,

I’m not sure. The test reports for the Biorock will show what quality of treatment you should expect (see e.g. http://biorock.co.uk/blogs/2013/1/biorock-independent-test-results) but whether that is good enough for *direct* usage as irrigation water is a different question; you might need some additional treatment.

It probably depends on what you are irrigating and personally I’d be a lot more careful with salad crops intended for human consumption than with something like fruit trees.

I know some American cities use treated waste water to irrigate parks and golf courses so if you can find out what sort of quality standard they treat the effluent to and compare that with the Biorock test reports that might give you a better idea. https://en.wikipedia.org/wiki/Reclaimed_water looks like a good starting point for further research.

David

Hi David

I am also in Mallorca and looking for something to process the grey water from a normal septic tank set up so it can be used for irrigation.

Perhaps we could compare notes?

Regards

David

I too am interested in the pricing you received from Biorock. There aren’t any installers in my area (NW Wisconsin, USA)… so I may be blazing a trail. We have a holding tank and no ability to have a drainage field. $1,000/year to pump the tank every 6 weeks (and there are only two of us using the system). I want to add on using their retrofit options. I’m sure the price will be significantly different considering you installed a new system. But, if you would share I would greatly appreciate it!

I’m not comfortable posting pricing details here but I’ll contact you via email.

David

Hi David.

We are looking to install the BioRock 3000L Primary tank with the 1500 Treatment tank however, we don’t have gravity on our side so are looking at the pump chamber also. One unusual requirement we have is it needs to be installed internally and, having again spoken to BioRock rep, so long as the vents are piped through the wall, this should be fine as the tanks are sealed and there is no off-gassing or odour leaks (apparently). Our local builder who we have converted the barn with up to now has experience of installing standard septic systems but this is a new one for him, so we are both learning as we go. One question I did have however was in regards to required permits. We are in the UK and will only be discharging an estimated 0.75m^3 of effluent a day (max as it isn’t constantly occupied) so think we could get an exemption from the UKs general binding rules for discharging to a water course. Have you had any dealings with the environment agency regarding your installation? For us, it is the best off-grid option as our solar electrical system wouldn’t cope with a permanent pump-aerated treatment plant going 24-7 so I’m trying to get ahead of the building controllers and environment agency wherever possible.

Great post by the way, like you say, the BioRock system isn’t widely known in the UK yet, so finding information on actual installations can be hard work.

Andy.

Hi Andy,

In terms of Environment Agency approval, that was handled by my installer. The EA need to be happy about *any* discharge into a water course but for less than 5m^3 of water per day from a type-approved treatment plant (i.e. one tested to achieve a good level of treatment) they typically grant an Exemption from needing a specific Permit to Discharge. You do however need to Register the installation with them, and they’ll send a certificate “Registering an Exempt Water Discharge Activity”. More info at https://www.gov.uk/permits-you-need-for-septic-tanks/general-binding-rules – there are various Conditions you need to comply with (including checking and maintaining the treatment plant) so the main concern is ensuring you can comply with those conditions. I’ll email you a copy of my certificate so you can see what all the conditions are.

In terms of an internal installation, it might be workable (as long as the vent-pipe runs are quite short) but the seals on the top of my tanks make no attempt to be air-tight. I reckon you’d need some sort of secondary enclosure over the top of the tanks, itself vented to the outside, while permitting access for inspection and maintenance. Like you say it’s an unusual thing to do and Building Control approval might be problematic.

David

Thank you David.

I’ll have a read and try to figure out what else I might need to do to make or keep the units properly vented.

The building control side has been difficult to explain up to now, but we have an inspector who has been really helpful so I’ll hopefully have him onside when I’ve spoken with the EA properly. Our initial plan was to use a holding tank and have regular pump-outs, but treating it at source is our obvious preference, not just from a cost perspective, but a safety and hygiene one so fingers crossed this option fits the bill.

Thanks again.

Andy.

Hi David,

Very interested in your review of the biorock system which you have had for? 6 years. How often does it have to be emptied and maintained?

Also I have read that the rocks need replacing after about 10 years at a cost of £700 for a 6 people system. We have 5 houses that share our system, bedroom 18 altogether so slightly worried about future cost of replacing rocks!

What area of the country are you in please? Sue

Hi Sue,

My system has a very easy life – sized for 10 people but there’s normally only me using it. I check it every year but so far it hasn’t needed emptying. The ‘rocks’ (actually foam cubes in string bags) still appear to be in good condition though I can believe they’ll need replacing at some point.

I’m in the East Midlands, near Derby.

David

Hi David

Firstly thank you for your informative site. It has been very useful as we are looking into purchasing a Biorock System for our piece of land by the river.

This seems the ideal solution as we are not always there so are looking for a system that does not require electrity. I know in previous posts you have said that you will forward installation costs to other people posting.

It would be really useful if you would be kind enough to give us some idea of the installation costs.

Your house looks absolutely superb by the way.

Kind Regards

Lance